What Is The Design Technique For The Spacing Of Min-piles? Biggest Civil Design Information Sharing Website Although there are lots of usages for micropiles, they are most frequently utilised to sustain brand-new or existing structures in position with little headroom as well as challenging gain access to. Various other uses micropiles are to give structural support, underpin foundations to get rid of settlement, improve dirt and slope security, as well as transfer tons to a steady dirt strata. The mini stack contractor should be accountable for the installation procedure. The micropile professional should have a complete understanding of the installment process, along with the devices and also products called for. They need to likewise be experienced in dealing with mini stacks and also have the ability to offer a detailed quote for the job. They are excellent for softer dirt conditions.Screw Mini PilesScrew mini stacks, likewise called helical piles, are twisted right into the ground utilizing a rotating hydraulic torque motor. They appropriate for a range of soil conditions and provide superb load-bearing capacity.Grouted Mini PilesGrouted mini heaps are constructed by injecting cement grout under stress into the borehole. Are commonly embraced to transfer the tons from the superstructure through weak strata onto the stiffer soils or rocks. Therefore, the dependability of pile-supported structures depends mainly on the behavior of the piles. There's no doubt, however, that mini piling has advantages in many situations. This particularly consists of situations where the stacking has to be performed in a confined space, since the devices is significantly smaller sized than what's required for traditional stacking. It's also great for built-up areas, considering that it creates less sound as well as vibrations, while still producing protected structures. Take into consideration a 406 mm size concrete stack with a length of 30m embedded in split, saturated clay. A support load bar is reduced right into the case, for added capacity. Heaps are placed by either driving, where the pile displaces the dirt, and boring, where a hole is produced the concrete or grout to be poured right into. Non-linear spring/damper designs can be used to design the dirt communication tons. Reinforcement bars are high-strength steel bars offered remains in sizes as much as 40mm and also generate strength till 460 MPa. The bearing soil or rock will establish their https://647a5afca6598.site123.me tons carrying capacity. The lack of necessary expenses or side website constraints that would prevent setups calling for significantly bigger devices is just one of the major advantages of utilizing micropiles. The cost of installing a micropile structure will vary relying on several factors, consisting of the kind of micropile being used, the deepness of the heaps, the dimension of the job, and the area.

Leading 5 Sorts Of Footings Made Use Of In Building Construction

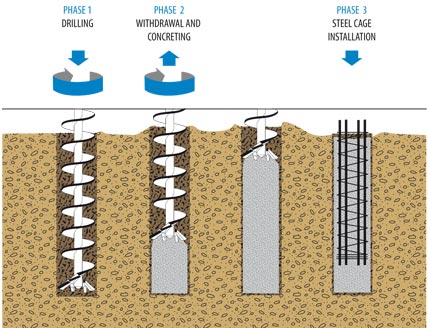

These piles are the best alternative for confined as well as remote areas like cellars, walkways, rivers, and also wetlands. Micropile structure is one of the extremely economical and trusted pile structures. In developing the axial capability of mini-piles, cement may be taken into consideration in the payment of axial tons capacity. Nonetheless, the overall load capability of min-piles may not be equivalent to the amount of specific capacity derived from cement as well as from steel H-section. Mini stacks work as a fundamental element in numerous building projects. Comprehending their function and also capability is vital to guarantee the success of your project.- This kind of micropile application is additionally known as a reticulated heap network.Designers should make certain that the pump ability will be sufficient to offer appropriate flow at the needed pressure in order to allow efficient procedures.Keller has substantial tons test experience in different rock developments and also the ability to develop in-house based upon various subsurface conditions.Mini piles are a popular and efficient method used in foundation building.Next off, grouting is performed sequentially under stress as the housing is slowly gotten rid of.Micro-piles are generally made from steel, but can likewise be made from concrete, grouted into place within a borehole.

32 Curving And Load Transfer System

Mini-pile foundations have promising potential customers due to low construction prices as well as mobile and also basic building and construction tools. The reason behind this is that the upright loads on mini-piles are shared among cement as well as steel sections based upon their Young's modulus and locations. Generally, in order to follow stress compatibility standard, the steel bars and also grout will certainly warp all at once though they have different rigidity. Thus, strain compatibility has to be signed in making the upright capacity of min-piles.Defending the City: An Overview of Defensive Tactics from the ... - mwi.westpoint.edu

Defending the City: An Overview of Defensive Tactics from the ....

Posted: Mon, 14 Feb 2022 08:00:00 GMT [source]