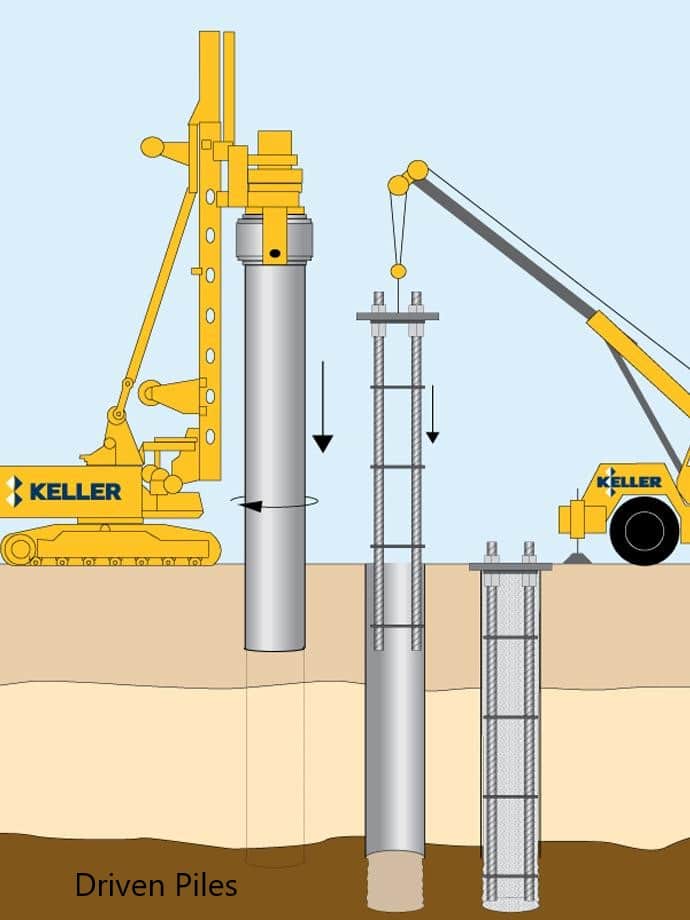

Micropile An Introduction There are two fundamental types of pile structures, each of which operates in its own method. The housings for the mini heaps are heaved up to a high of bedrock, which permits bonding to the bar. The construction of close-by structures demands the excavation of dirt sustaining existing structures. The API RP style codes ensure adequate structure security using the functioning tension layout method. Using micropiles is flexible sitting ground and also has actually been really effectively in many stability troubles, stress piles can be monetarily enhanced by the system once. In this situation, micropile is loaded under axial or flexure lots. The micropile housing normally has a diameter in the range of 3 to 10 inches. Enhancing steel, normally an piling contractors services in blackburn all-thread bar is put into the housing. The casing might extend to the complete deepness or end above the bond area, with the reinforcing bar including the full deepness. For the most typical type of mini piling, a hollow steel shaft is either screwed or drilled right into the ground. Grout or concrete can after that be gathered to form the heap, with the soil sustained throughout by the steel shaft. This implies that, unlike the conventional boring technique, no added assistances are needed, even in weak soil. Precast Driven Heaps are very first actors at ground level and afterwards hammered or driven into the ground making use of a heap motorist. This is a machine that holds the heap completely upright, and then hammers it right into the ground blow by strike. Each strike is is struck by raising a hefty weight and dropping it on the top of the heap - the heap is briefly covered with a steel cap to stop it from disintegrating. Care needs to be required to space the piles much enough apart to ensure that loads are dispersed uniformly over the whole bulb of dirt that brings them, as well as not concentrated into a few locations. As soon as you have pressed it in, it is strong sufficient to support some tons. The better theembedment depthin the gelato, the more load it can support. Tor steel support cage of a package of big size rebars is offered as stack reinforcement. A borehole of needed diameter 150 to 300 mm is pierced using bentonite slurry by a rotary boring devices to stabilize the sides of the birthed opening. Micro stacks as gone over earlier are screwed right into the soil to enhance its underpinning contractors in lancashire bearing capacity. Micropile is likewise a kind of helical stack however of smaller sized dimension.

- Micropiles typically require small small-sized equipment that can be utilized in restricted rooms with restricted access.However, based upon the grouting techniques, micropiles can likewise be split into four groups.' Standard support,' the mass concrete underpinning approach is almost 100 years in age, as well as the procedure has actually not altered.The API RP layout codes make sure adequate structure safety and security using the working stress layout method.Post-grouting among the bond length will certainly increase resistance pressures with close dirts, so accomplishing larger ability.

Delivery Steel Bar Aligning Cutting Device Argetina

The internal pressure created in batter stacks can be due to both the friction element as well as the bearing component or either of one. Once the stacks are driven right into the dirt, a cap of heaps is mounted. The caps of several piles can be collaborated, or they can be separately placed. Taking the situation of an upright pile unrestrained at the head, the lateral loading on the heap head is initially brought by the dirt short surface area. At a reduced loading, the soil presses elastically, however the movement suffices to move some pressure from the pile to the dirt at a better depth. At a more phase of loading, the dirt yields plastically, and the stack moves its lots to greater midsts. In both tension and also compression, mini stacks have high tons capability. Micropile foundation can be introduced at different angles and also these heaps can withstanding axial and lateral loads. The micro piles are best for reducing foundation settlement and also are optimal when is being done in the areas where soil make-up is rather hard. The stacks verticality and also size need to also be kept track of and also documented. A test stack is built at the beginning of the job and also load tested to 200% of the layout lots according to the conventional requirements ASTM D 1143. Micropiles can offer large compressional capacity along with great tensile ability. According to the industry (), micropiles have a functioning ability of up to 2200 kN. According to (), capabilities of about 500 tonnes have actually additionally been attained.Advantages Of Micropiles:

No safety covering is offered to the steel, as throughout driving, this would certainly be scraped away by the soil. In end bearing heaps, the lower end of the stack hinges on a layer of specifically strong dirt or rock. The lots of the structure is transferred with the pile onto the solid layer. The key principle is that the lower end hinges on the surface which is the intersection of a weak as well as solid layer. The lots for that reason bypasses the weak layer and is safely transferred to the solid layer.Cocaine-smuggling submarine reveals Europe's drug crisis - BBC

Cocaine-smuggling submarine reveals Helpful resources Europe's drug crisis.

Posted: Thu, 20 Apr 2023 07:00:00 GMT [source]