Precast concrete piles arc those which are made in a factory in a place away from the construction site, and afterwards driven into the ground at the area called for. Normally, these kinds of pile foundations call for heavy pile-driving machinery. Are generally taken on to transfer the loads from the superstructure with weak strata onto the stiffer soils or rocks. As a result, the dependability of pile-supported structures depends mainly on the behavior of the heaps. An important layout consideration is to check the load-- settlement features of heaps.

Which is the most usual kind of pile?

With a lot of structures, concrete piles are extra typical than the various other piles. The earliest type of the concrete heap is a cast-in-place pile.

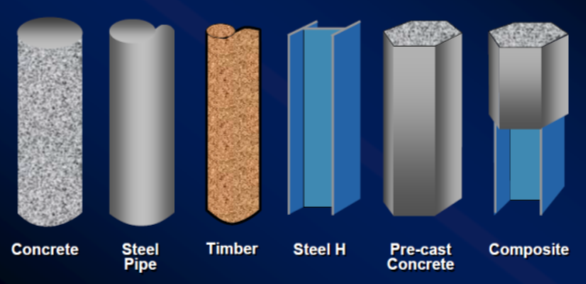

The agreement plans and also Conventional Plans are additional contract records needed for stack work and also define what stacking goes where for each structure. As a whole, the contract plans define the intended stack type, defined suggestion altitude and also a minimum small resistance. The contract specifications offer project-specific demands on just how to do the work. These documents likewise include details needs for activities such as embankment pre-drilling, lots screening, and also various other things certain to a task. As an example, if difficult driving is expected, the Developer might give the option of making use of either steel "H" piling or precast concrete piles. When this choice is composed right into the contract, the Contractor is allowed to choose the most economical alternative.

All The Basics On Concrete Supports: Functions, Installation, And Kinds

Sometimes larger sections are utilized to fulfill lasting solution demands. Cast-In-Drilled-Hole stacks are made of reinforced concrete cast right into holes pierced in the ground to a specified idea elevation. Sizes usually range from 12 to 168 inches and also sizes vary from 10 feet to well over 200 feet. They are adequate in ideal product and also are normally a lot more affordable than a lot of other types of stacking.

Bored heaps have the highest possible load ranking potential of all the pile foundation kinds. If created appropriately, some pile structure kinds can securely permit a future excavation to happen adjacent to them. This is not the instance for a lot of separated superficial pad foundations.

Concrete Heaps What Why When

Pile foundation transfers the tons with rubbing in addition to bearing. The steel stack is offered with a support internet inside the steel casing to enhance its load-bearing capacity. It has a higher load-bearing capacity when compared to the various other kinds of heaps as the concrete is extremely solid https://vxcelpiling.co.uk in compression.

Franki heap installation begins with insertion of a steel casing into the ground. The steel casing is driven via the soil layers with the assistance of a decrease hammer. Due to the tiny diameter and also short deepness of Micropiles, their installation differs slightly to tired stacks. Micro heaps are very comparable in nature to tired stacks however on a much smaller sized scale in terms of pile size as well as depth. The piles are after that installed using a gear with an effect hammer add-on. Like hammering a nail right into an item of lumber, the rig rams the pile right into the assistance soil until the desired capability is gotten to.

Uses Of Heap Structures

For a non-self sustaining soil a maintaining agent in the kind of bentonite slurry is circulated. The bentonite slurry travels with the drill stem to the base of opening and also moves up lugging the loosened up dirt. A slurry density of 10.5 to 12 KN/m3 suffices for security of the hole. The slurry is recycled after permitting the soil cutting to work out in a pond. It is a short duration test in which the pile is made is pass through in the soil at a constant rate. A common price of infiltration is 0.75 mm/min for clay and 1.5 mm/min for sand.

- Compaction piles do not bring load and for this reason they can be of weaker product.

- When 2 or more light bulbs are offered at the base, it is known as a multi-bulb under-reamed heap.

- When pipeline heaps are driven to weather-beaten rock or via stones, a cruciform end plate or a conical factor with rounded nose is typically used to stop distortion of the stack toe.

- While several meters of H-piles have actually been driven for rubbing applications, they are non-displacement heaps as well as have a tendency to drive even more in loose sands and silty sand.

- Anchor piles are used to resist the horizontal pull from sheet stacking or other pulling pressures.

They are created by driving a steel case in to the ground. The hole is after that loaded with concrete by putting the reinforcement and the covering is slowly raised. These heaps are driven right into the soil by the effect of hammer. When a stack is driven into granular dirts it densities the dirt as well as enhances toughness of dirt.

How Buffalo is clearing 80 inches of snow almost as fast as it fell - The Washington Post

How Buffalo is clearing 80 inches of snow almost as fast as it fell.

Posted: Tue, 22 Nov 2022 08:00:00 GMT [source]